The key technology of metal parts processing lies in material selection and surface treatment, which have a crucial impact on the performance and lifespan of metal parts.

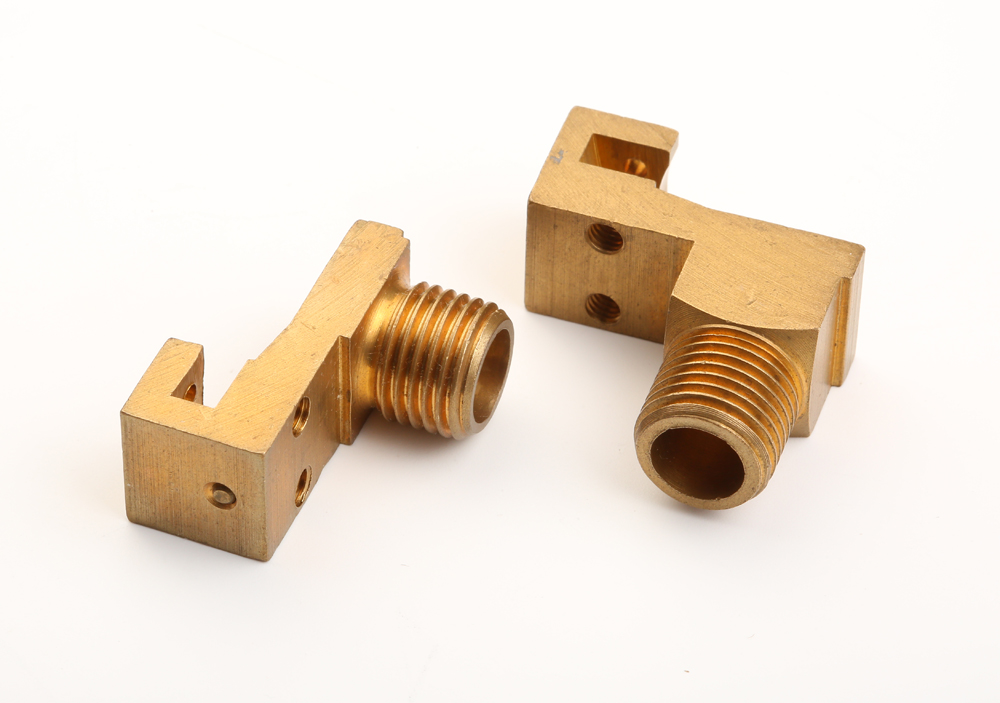

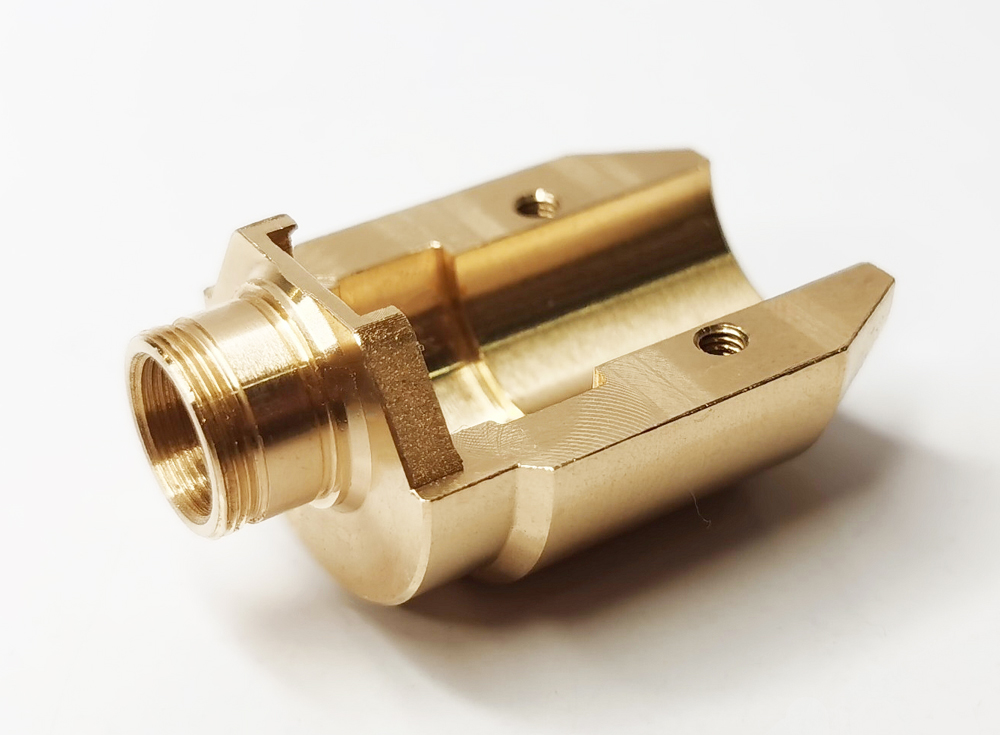

In terms of material selection, commonly used materials for hardware parts include stainless steel, aluminum alloy, brass, titanium alloy, and precious metals. Stainless steel is widely used in the manufacture of various hardware parts because of its excellent corrosion resistance and high strength. Aluminum alloys are lightweight and corrosion-resistant, and are often used in occasions where weight reduction is required. Brass still has a place in some high-end mechanical parts because of its good machining properties and electrical conductivity. Titanium alloys are very suitable for high-end hardware parts, especially sports products, due to their high strength, light weight, and no allergic reaction to the skin. Precious metals such as gold and platinum are often used in the manufacture of high-end luxury hardware parts because of their beautiful luxury and excellent oxidation and corrosion resistance.

In terms of material selection, commonly used materials for hardware parts include stainless steel, aluminum alloy, brass, titanium alloy, and precious metals. Stainless steel is widely used in the manufacture of various hardware parts because of its excellent corrosion resistance and high strength. Aluminum alloys are lightweight and corrosion-resistant, and are often used in occasions where weight reduction is required. Brass still has a place in some high-end mechanical parts because of its good machining properties and electrical conductivity. Titanium alloys are very suitable for high-end hardware parts, especially sports products, due to their high strength, light weight, and no allergic reaction to the skin. Precious metals such as gold and platinum are often used in the manufacture of high-end luxury hardware parts because of their beautiful luxury and excellent oxidation and corrosion resistance.

In terms of surface treatment, common treatment methods for hardware parts include electroplating, anodizing, polishing, sandblasting, etc. Electroplating can provide corrosion resistance to hardware parts and give them a bright or matte appearance. Anodizing can significantly improve the hardness and wear resistance of aluminum alloys, while increasing aesthetics. Polishing can make the surface of hardware parts smoother and improve their aesthetics and gloss. Sandblasting can enhance the texture and aesthetics of hardware parts, while improving the adhesion between the workpiece and the coating.

The key technology of metal parts processing lies in reasonable material selection and scientific surface treatment. In the actual processing process, it is necessary to comprehensively consider various factors such as the use environment, performance requirements and aesthetic requirements of the parts to choose the most suitable material and surface treatment process. Only in this way can we ensure that the hardware parts have excellent performance, long life and beautiful appearance, and meet the diverse needs of various industries and fields.

The key technology of metal parts processing lies in reasonable material selection and scientific surface treatment. In the actual processing process, it is necessary to comprehensively consider various factors such as the use environment, performance requirements and aesthetic requirements of the parts to choose the most suitable material and surface treatment process. Only in this way can we ensure that the hardware parts have excellent performance, long life and beautiful appearance, and meet the diverse needs of various industries and fields.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque