In material processing sites, people place great importance on processing equipment. The application of traditional processing methods usually requires complex operating procedures, requiring a large number of personnel to cooperate in order to complete the processing process. Although production tasks can also be completed, with the improvement of processing efficiency requirements in various industries, in order to improve work progress and complete processing tasks in a short time, it is necessary to start with the adjustment of equipment and operation methods. Therefore, many processing sites now pay attention to the application of vertical machining centers.

So what is the working principle of the vertical machining center? What are the advantages of this equipment in the working process? During the processing of the workpiece, the use of the equipment only requires the staff to enter the parameters according to the information processing standard. The application method of the equipment is very simple. After starting, only a simple clamping operation is required, and the equipment will enter the automation program. This equipment operation mode is carried out according to the parameter settings, and no personnel assistance is required. Therefore, the workflow has been simplified a lot compared with traditional equipment, and the running time is also shorter. What‘s more important is that the tools can now be replaced at will, and the machine tool can decide whether to increase the tool or change the processing speed.

Nowadays, vertical machining centers are equipped with a wide range of tools, so the equipment can meet the needs of different industries and processing sites. However, before the actual operation, the staff must have a detailed understanding of the working principle and application methods of the vertical machining center. equipment.

After the workpiece is clamped once in the machining center, the numerical control system can control the machine tool according to different processes, automatically select and replace the tool, automatically change the auxiliary features such as the spindle speed of the machine tool, the feed amount and the relative movement track of the tool to the workpiece, and complete the multi-process processing of multiple surfaces of the workpiece in turn. And it has a variety of tool change or tool selection functions, which greatly improves the production efficiency.

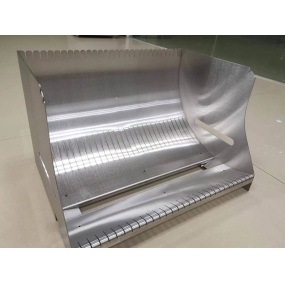

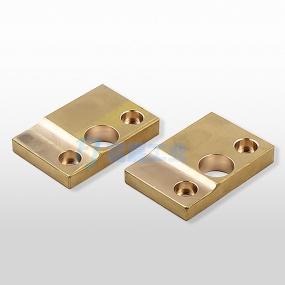

Vertical machining center refers to a set of machining centers with a spindle and a worktable vertical. It is mainly suitable for machining complex parts of plates, plates, molds and small shells. Vertical machining centers can complete processes such as milling, boring, drilling, tapping and cutting threads. Vertical machining centers are at least three-axis and two-linkage, and generally can realize three-axis and three-linkage. Some can be controlled by five-axis and six-axis. Vertical machining centers have limited height of columns and narrow machining range of box-type workpieces, which is the disadvantage of vertical machining centers. Vertical machining centers can be used for workpiece clamping, easy positioning; easy to observe tool movement trajectory, convenient inspection and measurement of debugging procedures, timely detection of problems, stop machining or modification; cooling conditions are easy to establish, and cutting fluid can directly reach the tool and machining surface. The three-coordinate axis is consistent with the Cartesian coordinate system, which feels intuitive and is consistent with the visual angle of the pattern. The chips are easy to remove and avoid scratching the machined surface. Compared with the corresponding horizontal machining center, the structure is simple, the footprint is small, and the price is lower.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque