A sudden COVID-19 in 2020 disrupted the rhythm of everyone. The country fought the epidemic at all costs, only to protect people‘s lives and health. The large shortage of masks has forced domestic mask manufacturers to increase production horsepower and introduce new equipment into production under the guidance and support of the government. The manufacture of mask production equipment also takes time. In order to win this battle without a fight, they can only work overtime. Some mask equipment accessories were originally processed with CNC and cut directly with high-efficiency lasers. Although the cost is high, the efficiency is high and the delivery time is short.

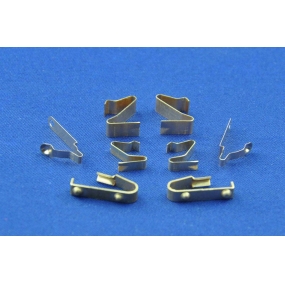

One to two medical disposable mask machine, one to one N95 mask machine, laser cutting of aluminum and iron processing parts, laser cutting of aluminum and iron processing parts of mask machine, laser cutting of aluminum and iron processing parts of mask machine, 8000W fiber disc laser cutting of Germany TRUMPF, mask machine All processing parts, laser cutting is fast, short delivery time, EMAR‘s 8000W equipment of Germany TRUMPF is the time to play its advantage.

In order to allow everyone to use masks as soon as possible, EMAR Sheet Xin Factory does its best to stay up all night, day and night, with powerful German equipment, full power, mask machine aluminum baseplate laser cutting, stainless steel processing parts, all can be laser cut, aluminum iron 1-25MM cut casually. In order to win the fight against the epidemic, all orders related to mask machines will be given the green light from now on, three sets of equipment for stainless steel processing parts, special period, I hope all regular customers can understand.

In order to allow everyone to use masks as soon as possible, EMAR Sheet Xin Factory does its best to stay up all night, day and night, with powerful German equipment, full power, mask machine aluminum baseplate laser cutting, stainless steel processing parts, all can be laser cut, aluminum iron 1-25MM cut casually. In order to win the fight against the epidemic, all orders related to mask machines will be given the green light from now on, three sets of equipment for stainless steel processing parts, special period, I hope all regular customers can understand.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque