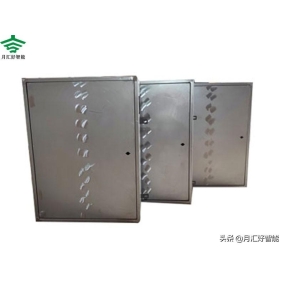

Numerical control technology has been used more and more with the rapid development of Sheet Metal Processing. Numerical control punches, numerical control shearing machines, numerical control bending machines, etc. are all mechanical equipment often used in sheet metal processing. Non-standard cabinet customization A professional sheet metal processing manufacturer provides customers with a variety of standard or non-standard sheet metal processing products. What are the processes of numerical control sheet metal processing? (1) Simple and convenient to use, low investment cost. It has its own unique advantages in the processing of various sheet metal parts, especially for the processing of complex shapes or thin plate parts, which can automatically complete the processing of parts. According to the requirements of the drawings, the holes with different size requirements and shape requirements can be automatically processed, and the larger holes and contour curves of various shapes can be produced and processed in a small step-by-step manner using small punching dies. In addition, the simple structure of the die can also be processed for sheet metal parts with special processing techniques, such as shallow stretching, flanging holes, etc. Compared with traditional stamping, the die is simpler, the processing range is wide, and the processing capacity is significantly improved. It is particularly suitable for mass production or various forms of product processing. This is very beneficial for processing enterprises to keep up with the pace of market development and meet product demand. Moreover, because of the reduction of costs in all aspects, the economic benefits of the enterprise have been effectively improved. (2) The product quality is stable and the processing accuracy is high. For the processing of sheet metal parts, the workpiece has good flatness, higher punching accuracy, and the burr brother, the forming quality is stable, and the product has good consistency. (3) Effectively improve production efficiency. The automatic control system can realize the processing of small batches of workpieces and the simultaneous processing of different parts, and the processing speed is fast. Because the subsequent processing and other links are reduced for the numerical control integrated processing of sheet metal parts, the production is greatly improved and the production cost is reduced.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque