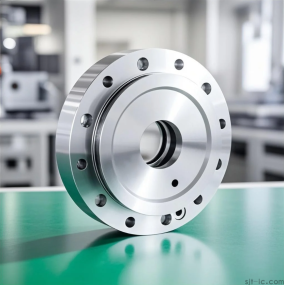

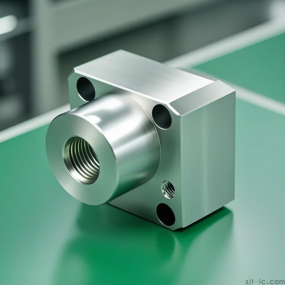

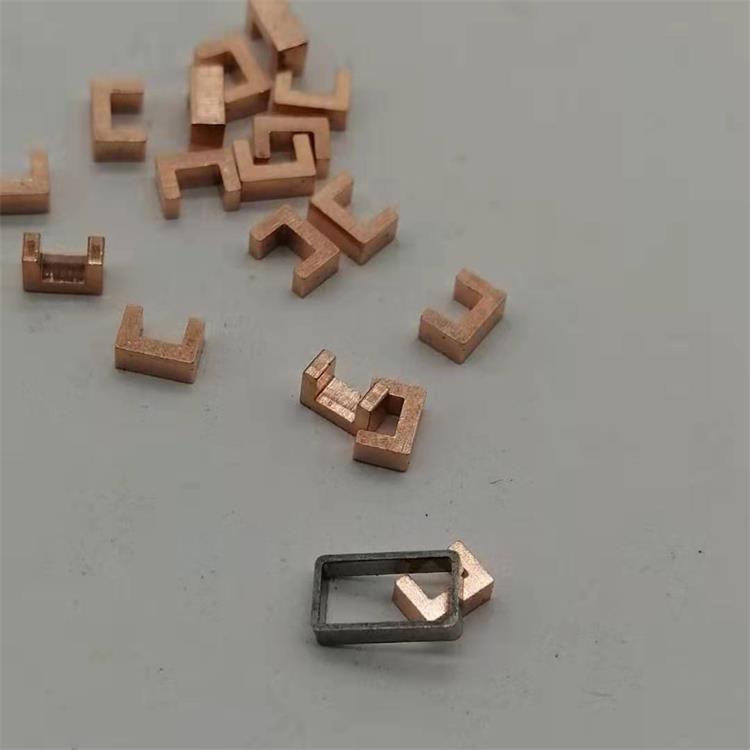

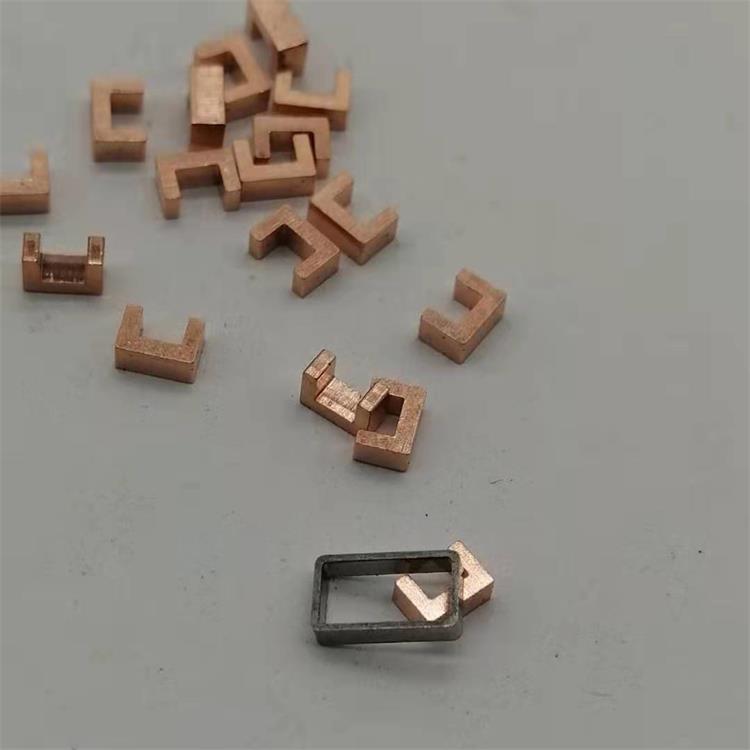

Precision cold extrusion machining process will completely change the low efficiency mode of some numerical control vehicles and win the speed of CNC. Have you ever seen a device that processes more than 300 micro-precision parts per minute? Tell you that it is not a cold pier machine. Although the cold heading machine can achieve this speed, it cannot achieve the precision! The current precision cold extrusion machining process uses high-precision high-speed punching machines and high-precision molds to easily control the precision of parts and products at plus or minus 0.02mm, and the fastest speed can reach more than 350/min. The CNC Machining speed of the numerical control vehicle is far behind. It is even more rare and valuable to process parts. The molecules change the arrangement direction. The strength is more than 2 times that of the raw materials. The coexistence of speed and accuracy is a huge advantage of precision cold extrusion machining. It kills most CNC numerical control machining in seconds. However, the technological disadvantage of precision cold extrusion machining has to be mentioned, that is, the mold cost is relatively expensive, and the product needs to have a huge market demand. Otherwise, the amortization of the mold will cover up the cost advantage of the parts. At present, this new technology of precision cold extrusion machining has been widely involved in the manufacture of 5G parts, providing a low-cost solution for the huge micro hardware parts market. When it comes to the mature process of precision cold extrusion machining, it is necessary to mention EMAR hardware‘s decades of technological research and development achievements and equipment investment, which has made precision cold extrusion machining technology in a leading position in domestic technology. The following picture is a product made by precision cold extrusion machining process. Please refer to it!

Precision cold extrusion machining process will completely change the low efficiency mode of some numerical control vehicles and win the speed of CNC. Have you ever seen a device that processes more than 300 micro-precision parts per minute? Tell you that it is not a cold pier machine. Although the cold heading machine can achieve this speed, it cannot achieve the precision! The current precision cold extrusion machining process uses high-precision high-speed punching machines and high-precision molds to easily control the precision of parts and products at plus or minus 0.02mm, and the fastest speed can reach more than 350/min. The CNC Machining speed of the numerical control vehicle is far behind. It is even more rare and valuable to process parts. The molecules change the arrangement direction. The strength is more than 2 times that of the raw materials. The coexistence of speed and accuracy is a huge advantage of precision cold extrusion machining. It kills most CNC numerical control machining in seconds. However, the technological disadvantage of precision cold extrusion machining has to be mentioned, that is, the mold cost is relatively expensive, and the product needs to have a huge market demand. Otherwise, the amortization of the mold will cover up the cost advantage of the parts. At present, this new technology of precision cold extrusion machining has been widely involved in the manufacture of 5G parts, providing a low-cost solution for the huge micro hardware parts market. When it comes to the mature process of precision cold extrusion machining, it is necessary to mention EMAR hardware‘s decades of technological research and development achievements and equipment investment, which has made precision cold extrusion machining technology in a leading position in domestic technology. The following picture is a product made by precision cold extrusion machining process. Please refer to it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque