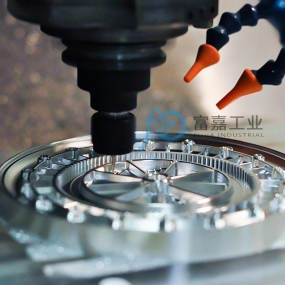

Human technology is increasingly advancing towards a high degree of intelligence, and the demand for various types of sensors is increasing. So where can high-precision sensor shells be produced? EMAR Hardware adopts two production methods: continuous die cold extrusion and continuous die stretching! Especially good at the production of miniature precision sensor shells. For thin-walled sensor shells, it is produced by stretching, and for wall-thick sensor shells, it is produced by cold extrusion. The precision of both methods can reach a tolerance of 0.02mm, and the production efficiency is very high, and the fastest production speed can reach 150 pcs/min. The following are the pictures of representative sensor shells produced by EMAR Hardware. If you are interested, please visit and leave a message to me in my comment area!

Human technology is increasingly advancing towards a high degree of intelligence, and the demand for various types of sensors is increasing. So where can high-precision sensor shells be produced? EMAR Hardware adopts two production methods: continuous die cold extrusion and continuous die stretching! Especially good at the production of miniature precision sensor shells. For thin-walled sensor shells, it is produced by stretching, and for wall-thick sensor shells, it is produced by cold extrusion. The precision of both methods can reach a tolerance of 0.02mm, and the production efficiency is very high, and the fastest production speed can reach 150 pcs/min. The following are the pictures of representative sensor shells produced by EMAR Hardware. If you are interested, please visit and leave a message to me in my comment area!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque