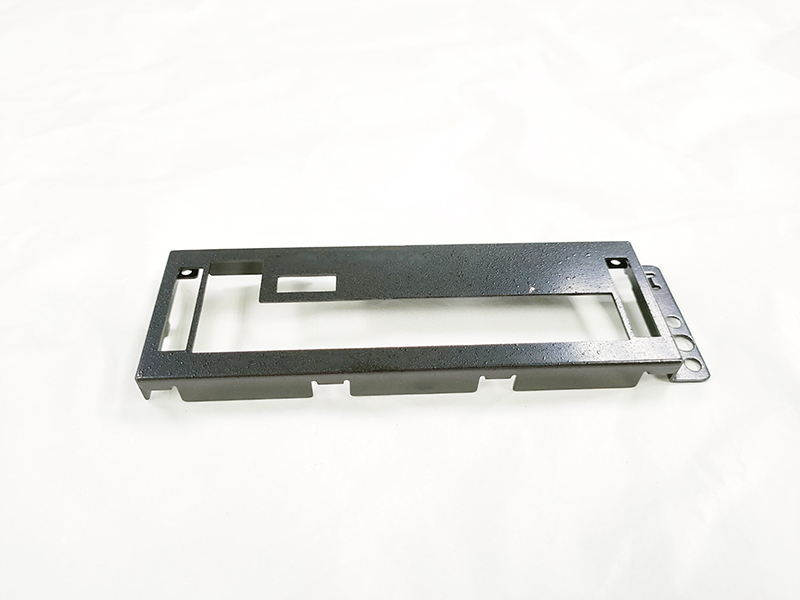

In a Metal Stamping processing plant, the production and processing of a metal stamping part requires multiple production steps from the first step to the finished product. The following small series will tell you what production processes you generally go through. ANd Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

1. Blanking: Blanking of stamped parts is the first process of stamping processing. According to the requirements of the drawing, the steel plate is cut into the required sheet or strip. 2. Punching: The metal plate (or pipe) is cut into the desired shape and size according to the size of the drawing. 3. Bending: The radius of curvature of the sheet is reduced; 4. Drawing: The thickness of the sheet is thinned to reduce the wall thickness of the metal stamping stamped parts;  5. Forming: By stretching the material to form a certain shape of the workpiece; 6. Finishing; trimming burrs and flying edges, etc.; 7. Inspection: Measuring whether the parameters such as dimensional tolerance and shape and position deviation of the part meet the design requirements. 8. Packaging: Packing and labeling and warehousing. What I want to explain here is what stamping process and production steps are taken for a metal stamping stamping part, which is related to the shape, size and accuracy of the stamping part. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping processing, hardware stamping, CNC lathe processing and other information, sincerely welcome people from all walks of life to visit our factory to negotiate and guide, we will serve you wholeheartedly. ANd Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

5. Forming: By stretching the material to form a certain shape of the workpiece; 6. Finishing; trimming burrs and flying edges, etc.; 7. Inspection: Measuring whether the parameters such as dimensional tolerance and shape and position deviation of the part meet the design requirements. 8. Packaging: Packing and labeling and warehousing. What I want to explain here is what stamping process and production steps are taken for a metal stamping stamping part, which is related to the shape, size and accuracy of the stamping part. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping processing, hardware stamping, CNC lathe processing and other information, sincerely welcome people from all walks of life to visit our factory to negotiate and guide, we will serve you wholeheartedly. ANd Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque