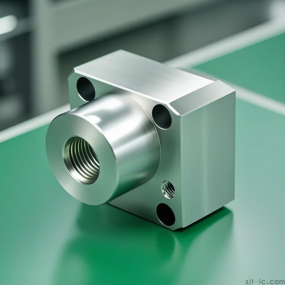

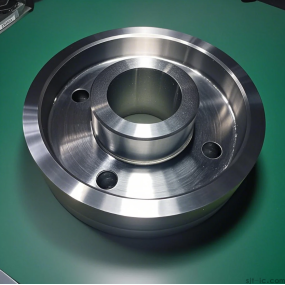

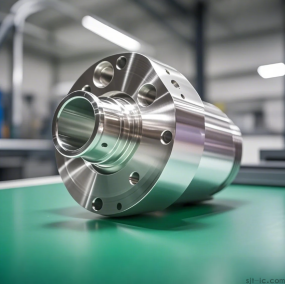

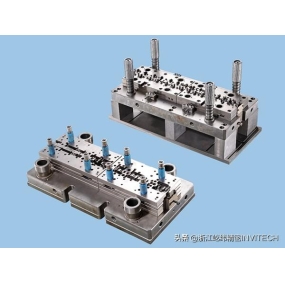

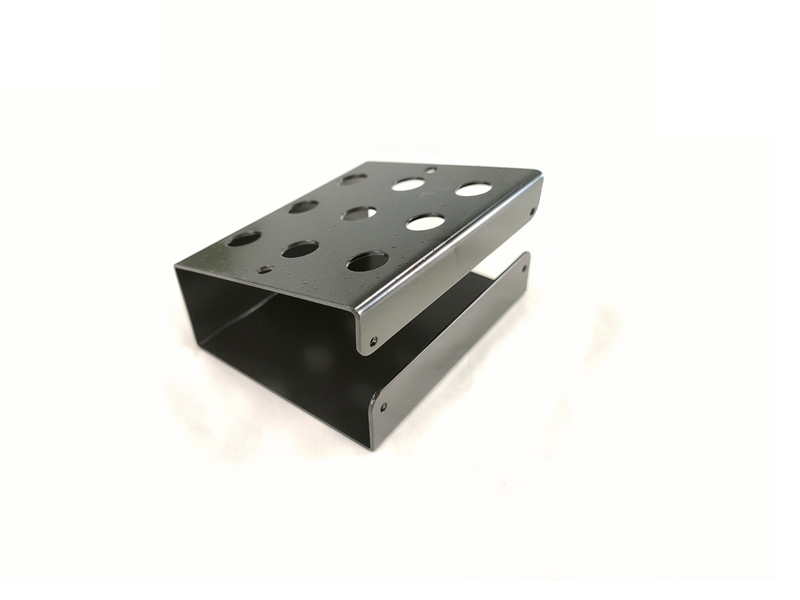

The processing of Metal Stamping parts in a hardware processing plant must be done with the help of molds. A mold is an industrial product that forms materials in a certain way in a specific structural form, and it is also a production tool that can produce industrial product parts with certain shape and size requirements in batches. The molds used by metal stamping parts manufacturers are usually cold stamping dies. The following are several types of molds commonly used in stamping parts factories. JCA Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

First, punching die: on the blank or sheet, along the closed contour to separate out the waste to get the punching die with holes. Second, drawing die: to ensure the production of qualified cover parts of the most important equipment, its role is to flat-shaped wool through the drawing process to become the main space workpiece, divided into formal and flip-flop two forms. Third, trimming die: used to metal processing drawing parts of the process supplement part and the excess part of the pressing flange removal, for flanging and shaping preparation conditions, in small batch production, can be replaced by manual or other simple equipment, trimming die often also punching.  4. Flanging die: It is a part of the material of the workpiece working in progress that is flipped relative to another part of the material. 5. Shaping die: A die that will work in progress to adjust the dimensional profile to improve dimensional accuracy and surface finish. Of course, there are many types of stamping dies for hardware processing, and today I will introduce these kinds first. It is worth noting that when processing metal stamping parts, different production processes use different stamping dies. Stamping parts with simple shapes and structures need one or two sets to obtain, but the processing of complex stamping parts sometimes requires as many as a dozen sets of dies. The number of sets of stamping dies is directly related to the cost of stamping parts, so when formulating the stamping process, we should reduce the production process as much as possible under the premise of ensuring quality, so as to reduce the number of die sets and reduce production costs, while also reducing the scrap rate. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, metal processing, sheet metal factories, metal stamping processing, metal stamping processing, CNC lathe processing and other information. We warmly welcome people from all walks of life to visit our factory to negotiate and guide, and we will serve you wholeheartedly.

4. Flanging die: It is a part of the material of the workpiece working in progress that is flipped relative to another part of the material. 5. Shaping die: A die that will work in progress to adjust the dimensional profile to improve dimensional accuracy and surface finish. Of course, there are many types of stamping dies for hardware processing, and today I will introduce these kinds first. It is worth noting that when processing metal stamping parts, different production processes use different stamping dies. Stamping parts with simple shapes and structures need one or two sets to obtain, but the processing of complex stamping parts sometimes requires as many as a dozen sets of dies. The number of sets of stamping dies is directly related to the cost of stamping parts, so when formulating the stamping process, we should reduce the production process as much as possible under the premise of ensuring quality, so as to reduce the number of die sets and reduce production costs, while also reducing the scrap rate. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, metal processing, sheet metal factories, metal stamping processing, metal stamping processing, CNC lathe processing and other information. We warmly welcome people from all walks of life to visit our factory to negotiate and guide, and we will serve you wholeheartedly.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque