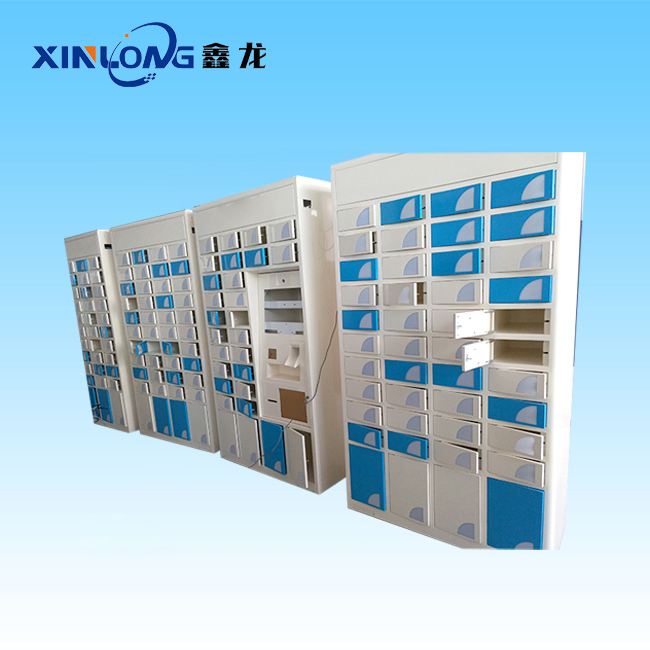

I. Functional requirements ① Convenience of operation: Sheet metal rack processing The appearance design of the sheet metal rack must meet its functional requirements and be easy to operate and use. The design should take into account the user‘s operating habits and convenience, and provide a clear operation interface and ergonomic principle structure to facilitate the installation, maintenance and debugging of the user. ② Equipment stability: The appearance design of the rack should ensure that the equipment has sufficient stability during use to prevent the equipment from shaking or tipping due to structural problems.  II. Safety requirements ① Safety standards: Sheet metal rack processing design should comply with relevant safety standards and specifications to ensure the safe operation and operation of the equipment. The personal safety of the operator must be taken into account to avoid sharp corners, protrusions and other design elements that may cause harm. ② Protective design: For parts that may cause danger, such as moving parts, high temperature areas, etc., corresponding protective devices or warning signs should be designed to remind the operator to pay attention to safety. III. Aesthetic requirements ① Overall style: Sheet metal rack processing The appearance design of the sheet metal rack should comply with aesthetic principles, and pay attention to the simplicity, fluency and integrity of the design. The overall style should be coordinated with the use of the equipment and the environment, showing a sense of modernity and technology. ② Color matching: The choice of color should be solemn and elegant, even and stable. It is not only suitable for people‘s use and control, but also easy to distinguish. It also requires generous color and can match the main body. At the same time, the color matching should also take into account the brand perception and market positioning of the product. Four, material and process requirements ① Material selection: Sheet metal rack processing The choice of appropriate materials can affect the appearance texture and durability of the product. Sheet metal rack material should have good processing performance, corrosion resistance and wear resistance and other characteristics to ensure the service life and appearance quality of the product. ② Process technology: Exquisite process technology can improve the manufacturing quality and surface finish of the product. In the processing process, the process parameters and processing accuracy should be strictly controlled to ensure that the appearance quality of the product meets the design requirements. Five, other requirements ① Environmental protection requirements: Sheet metal rack processing process should meet the requirements of environmental protection, reduce the impact on the environment. In material selection and process design, priority should be given to environmentally friendly materials and technologies to reduce the emission of harmful substances and waste of resources. ② Brand Identity and Differentiation: The appearance design should be able to highlight the brand characteristics and enhance the brand identity. Through unique design elements and brand identity, the sheet metal rack can stand out in the market and establish brand perception and recognition. ③ User experience and feedback: The user experience and feedback should be fully considered in the process of sheet metal rack processing and design. Continuously improve the design to enhance the user experience and satisfaction of the product by collecting user opinions and needs.

II. Safety requirements ① Safety standards: Sheet metal rack processing design should comply with relevant safety standards and specifications to ensure the safe operation and operation of the equipment. The personal safety of the operator must be taken into account to avoid sharp corners, protrusions and other design elements that may cause harm. ② Protective design: For parts that may cause danger, such as moving parts, high temperature areas, etc., corresponding protective devices or warning signs should be designed to remind the operator to pay attention to safety. III. Aesthetic requirements ① Overall style: Sheet metal rack processing The appearance design of the sheet metal rack should comply with aesthetic principles, and pay attention to the simplicity, fluency and integrity of the design. The overall style should be coordinated with the use of the equipment and the environment, showing a sense of modernity and technology. ② Color matching: The choice of color should be solemn and elegant, even and stable. It is not only suitable for people‘s use and control, but also easy to distinguish. It also requires generous color and can match the main body. At the same time, the color matching should also take into account the brand perception and market positioning of the product. Four, material and process requirements ① Material selection: Sheet metal rack processing The choice of appropriate materials can affect the appearance texture and durability of the product. Sheet metal rack material should have good processing performance, corrosion resistance and wear resistance and other characteristics to ensure the service life and appearance quality of the product. ② Process technology: Exquisite process technology can improve the manufacturing quality and surface finish of the product. In the processing process, the process parameters and processing accuracy should be strictly controlled to ensure that the appearance quality of the product meets the design requirements. Five, other requirements ① Environmental protection requirements: Sheet metal rack processing process should meet the requirements of environmental protection, reduce the impact on the environment. In material selection and process design, priority should be given to environmentally friendly materials and technologies to reduce the emission of harmful substances and waste of resources. ② Brand Identity and Differentiation: The appearance design should be able to highlight the brand characteristics and enhance the brand identity. Through unique design elements and brand identity, the sheet metal rack can stand out in the market and establish brand perception and recognition. ③ User experience and feedback: The user experience and feedback should be fully considered in the process of sheet metal rack processing and design. Continuously improve the design to enhance the user experience and satisfaction of the product by collecting user opinions and needs.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque