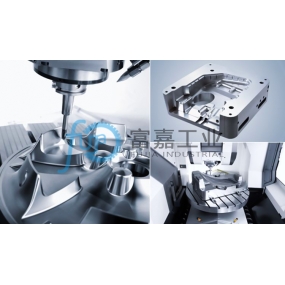

Repeated production CNC numerical control lathe processing part: the use of numerical control grinding process preparation time occupies a higher proportion. Process analysis preparation, such as programming, part first adjustment test cutting, etc., the sum of comprehensive working time is often dozens to 100 times the processing hours of individual parts, but these numerical control lathes can be stored and used repeatedly, so a part of the numerical control grinder repeated trial production successfully put into production, greatly reducing the production cycle, reducing costs, can achieve better economic benefits.

To ensure the processing quality of the key and effective production of small and medium-sized batches of key parts: numerical control grinder can achieve high precision, high quality, high efficiency grinding under computer control. This is a special grinder processing can save a lot of special process equipment, has strong flexible capacity, and obtain good economic benefits. Compared with ordinary grinding, it can eliminate many artificial interference factors of complex processing process flow, good consistency and interchangeability of precision parts processing, high processing efficiency.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque