The whole process of processing non-standard lathe parts in the hardware industry, from design drawings to finished product delivery, mainly includes the following key links:

1. Demand communication and drawing confirmation: First, the customer communicates with the processing manufacturer to clarify the specific requirements of the processed parts, including material, size, shape, accuracy, etc. Then, the customer provides drawings or detailed descriptions, and the processing manufacturer reviews the drawings to ensure that the processing requirements are clear and the drawings are accurate.

1. Demand communication and drawing confirmation: First, the customer communicates with the processing manufacturer to clarify the specific requirements of the processed parts, including material, size, shape, accuracy, etc. Then, the customer provides drawings or detailed descriptions, and the processing manufacturer reviews the drawings to ensure that the processing requirements are clear and the drawings are accurate.

2. Process formulation and preparation: According to the drawings and requirements, the processing manufacturer formulates a detailed processing technology, including selecting tools, setting processing parameters, and determining the processing sequence. At the same time, the processing equipment is debugged to ensure accuracy and stability, and the required fixtures and other auxiliary tools are prepared.

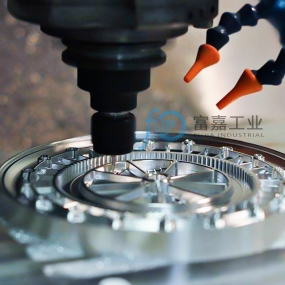

3, production and processing: the use of numerical control lathes and other equipment for processing, through precise programming and control, in accordance with the roughing, semi-finishing, finishing sequence gradually completed to ensure the processing accuracy and surface quality.

4. Quality inspection: Conduct a comprehensive quality inspection of the finished parts, including dimensional inspection, appearance inspection, performance testing, etc., to ensure compliance with customer requirements and relevant standards.

4. Quality inspection: Conduct a comprehensive quality inspection of the finished parts, including dimensional inspection, appearance inspection, performance testing, etc., to ensure compliance with customer requirements and relevant standards.

5. Delivery: Deliver qualified parts to customers and provide necessary after-sales services and technical support. Before delivery, check all fasteners and joint connections to ensure that they are fastened in place and reliable, and clean the surface of the equipment and paste the necessary signs and labels.

The entire process requires a high degree of professionalism and precision to ensure the quality and performance of the final product. With the development of industrial automation and intelligent manufacturing, the efficiency and precision of non-standard lathe parts processing will continue to improve to meet more diverse and personalized needs.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque