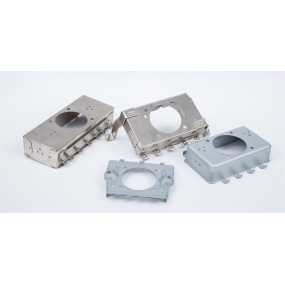

Each type of product has different regulations for aluminum shells. The actual situation is mainly manifested in the appearance, specifications, etc. Anyone who has touched aluminum shell processing knows that there are two processing processes in the manufacturing industry, namely CNC processing, die casting processing, aluminum shell processing, and other processes. Let‘s take a look at the relevant content below.

The differences between CNC Machining and die casting machining of aluminum shells:

Processing methods are different:

CNC machining of aluminum shell refers to the precise numerical control processing of it by computer, and the finishing of aluminum shell under the control of computer. Under this processing technology, aluminum shell can achieve some very special or complex surface treatment, such as oblique cutting, non-penetrating pattern or texture engraving, punching at the bend of aluminum shell, surface treatment of non-flat plane, etc., can be completed in CNC machining. Manufacturers with personalized and high requirements for custom machining of aluminum shell generally inevitably apply to this category.

The process of die casting involves applying high pressure to the molten metal using a die cavity to form a surface effect similar to that of a mold. During the die casting process, some simple punching and molding can be performed, which is relatively inexpensive compared to CNC machining. However, very complex surface treatment cannot be performed.

The biggest difference between aluminum shell numerical control processing and die casting processing is the processing method. It can also be seen from the above that in order to produce and process qualified aluminum shells, it is necessary to choose the corresponding processing technology according to its production needs. In addition, we must also consider the production cost. When both processing technologies are feasible, which one is more convenient and beneficial to choose, rather than which one looks better. After all, which one is more favorable. After all, which one is more suitable for you is very important.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque