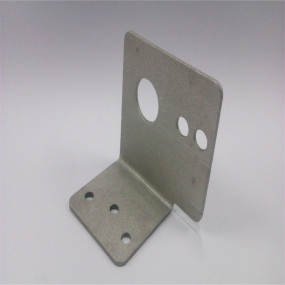

In the stamping process of sheet metal brackets, accuracy and efficiency are two crucial requirements. The following is a detailed analysis of these two requirements: 1. Precision requirements ① Classification of machining accuracy: Precision of sheet metal parts in the initial processing: This accuracy corresponds to the accuracy requirements of sheet metal parts in the initial processing process, that is, in the process of cutting, punching, etc. This accuracy level requires a lower accuracy, which is generally controlled within the error range of 1-2mm.  Sheet metal parts Finishing accuracy: This accuracy corresponds to the accuracy requirements of sheet metal parts in the finishing process, such as bending, forming and other processes. This accuracy level requires higher than the initial processing, and is generally controlled within the error range of 0.5-1 mm. Sheet metal parts special processing accuracy: This accuracy corresponds to the needs of sheet metal parts in some process links that require special precision, such as laser cutting, laser welding and other processing requirements. This accuracy level requires the highest, generally controlled within the error range of 0.1-0 mm. ② Machining accuracy content: Dimensional accuracy: used to limit the range of dimensional error between the machined surface and its reference. Shape accuracy: used to limit the macro geometric error of the machined surface. Position accuracy: used to limit the parallelism, verticality, coaxiality and other mutual position errors between the machined surface and its reference. Second, efficiency requirements ① Process optimization: The design requirements should minimize the number of stamping processes, simplify the process flow as much as possible, and improve production efficiency. In the stamping process, it is necessary to take into account the characteristics of stretching, shrinkage and elastic recovery of materials, and rationally design the stamping and forming processes. ② Application of digital technology: The application of digital technology makes Sheet Metal Processing can realize the integration from design to production, which greatly improves the production efficiency and accuracy. ③ Equipment selection: Sheet metal processing equipment includes numerical control cutting machine, stamping machine, bending machine, welding machine, etc. The performance and accuracy of these equipment directly affect the quality and production efficiency of sheet metal products. Therefore, it is very important to choose the right equipment. ④ Environmental protection and energy saving: With the improvement of environmental awareness, sheet metal processing enterprises also pay more attention to environmental protection and energy saving, which is also a way to improve production efficiency.

Sheet metal parts Finishing accuracy: This accuracy corresponds to the accuracy requirements of sheet metal parts in the finishing process, such as bending, forming and other processes. This accuracy level requires higher than the initial processing, and is generally controlled within the error range of 0.5-1 mm. Sheet metal parts special processing accuracy: This accuracy corresponds to the needs of sheet metal parts in some process links that require special precision, such as laser cutting, laser welding and other processing requirements. This accuracy level requires the highest, generally controlled within the error range of 0.1-0 mm. ② Machining accuracy content: Dimensional accuracy: used to limit the range of dimensional error between the machined surface and its reference. Shape accuracy: used to limit the macro geometric error of the machined surface. Position accuracy: used to limit the parallelism, verticality, coaxiality and other mutual position errors between the machined surface and its reference. Second, efficiency requirements ① Process optimization: The design requirements should minimize the number of stamping processes, simplify the process flow as much as possible, and improve production efficiency. In the stamping process, it is necessary to take into account the characteristics of stretching, shrinkage and elastic recovery of materials, and rationally design the stamping and forming processes. ② Application of digital technology: The application of digital technology makes Sheet Metal Processing can realize the integration from design to production, which greatly improves the production efficiency and accuracy. ③ Equipment selection: Sheet metal processing equipment includes numerical control cutting machine, stamping machine, bending machine, welding machine, etc. The performance and accuracy of these equipment directly affect the quality and production efficiency of sheet metal products. Therefore, it is very important to choose the right equipment. ④ Environmental protection and energy saving: With the improvement of environmental awareness, sheet metal processing enterprises also pay more attention to environmental protection and energy saving, which is also a way to improve production efficiency.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque