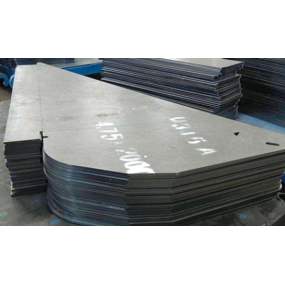

Sheet Metal Processing manufacturers have more than ten years of production and processing experience in sheet metal processing. Sheet metal processing belongs to a kind of metal processing, but its use is not limited to metal processing. Sheet metal processing generally uses hot processing and cold processing. How to choose the two processes needs to be used according to specific requirements and regulations. Sheet metal processing uses various cutting tools and equipment to cut off the excess metal, and then uses various forming molds to cast the metal into the shape we want. Sheet metal processing requires relatively high shape and size of sheet metal parts, so drawings will be drawn in the early stage to determine the order of each processing process. Cutting methods include turning, drilling, milling, planing, grinding, broaching, etc. In the metal processing technology, cold working is the corresponding to hot working. Cold working refers to the processing technology that causes plastic deformation of metal at a temperature lower than the recrystallization temperature, such as cold rolling, cold drawing, cold forging, stamping, cold extrusion, etc. Cold working technology can increase the resistance to deformation of metals. While forming metal parts, various metal fusion can be used to improve strength and hardness. However, cold working will reduce the plasticity of metals. Generally, the metal will be made into a suitable model first and then cold working process. Cold working is suitable for processing metal parts with small cross-section size and high processing size and surface roughness requirements.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque