2019 is coming to an end. In this year of struggle, we have gained the trust of many new customers and also carried out sheet metal laser cutting for different applications, especially our advantageous position of TRUMPF 8000W laser cutting processing, which gives us a certain position in the industry. In many processing industry circles, as long as there are some copper and aluminum materials that need lasers, we will think of a very cost-effective and fast processing method, that is, laser cutting processing, and we have German origin 8000W laser cutting equipment.

Please tell friends in need: laser cutting processing selection EMAR, copper, aluminum and other materials can be cut, and anyone who comes will not refuse!

In the cold winter, we also have to choose to run hard. In addition to running forward, we have no choice but to adhere to the front line of Sheet Metal Processing, professional laser cutting processing, no distractions, and hard work. In the age of reshuffle, we need to achieve higher quality and higher requirements. When new and old customers think of us and want to place an order, our EMAR is always on standby, and returns the trust of customers with high-quality products.

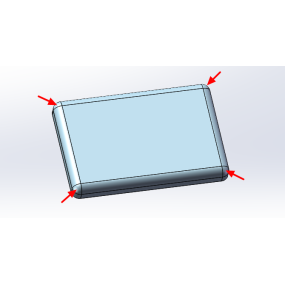

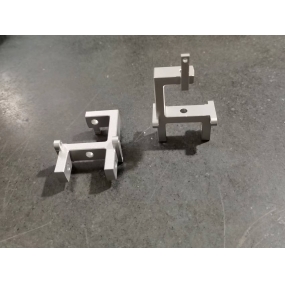

EMAR sheet metal factory has been renovated, 8000W laser cutting equipment and personnel are all ready, and they will be working at full capacity before the end of the year. New and old customers are welcome to place orders vigorously, cost and quality delivery, sheet metal processing and equipment are readily available, automated machine and sheet metal one-stop service, optimized process design team. Welcome aspiring talents to join us, we will continue to grow our team and work hard for the new journey in the coming year.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque